Internals For Structured PackingINTERNAL FOR REGULAR PACKINGS

Metal

You can see detailed explanation if you hover the mouse over an arrow of the tower.

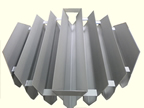

MC distributor

Support grid

Wall wiper

Collector

MC distributor

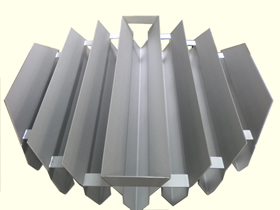

Column Internals which disperse equally liquid on face of packing.

MC distributor can uniformly get packing wet by the groundbreaking number of drip points(More than 1000/m3) and can bring out ability of packing at full.

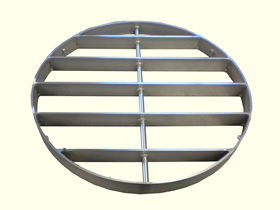

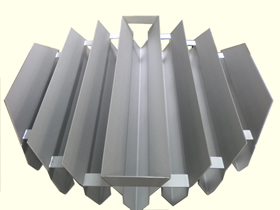

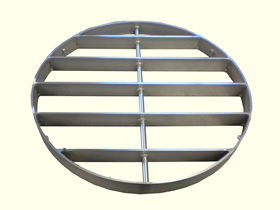

Support grid

Column Internals for supporting packing.

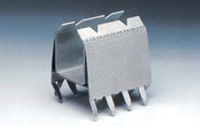

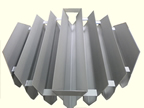

Wall wiper

Parts in column for collecting liquid flowing down on a wall to the center of column.

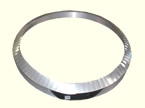

Collector

Parts in column which liquid flowing down from the upper packing layer is collected to the distributor by.

MC distributor

MC distributor Water dispersion test.

NOZZLE OVERFLOW TYPE

- A hole is located on the upper surface of a pipe, through which a liquid flows out. It prevents an absence of liquid and helps maintain the constant

volume of flow under extremely low load.

- A diffuser plate and clicks on a lower side allow a liquid to spread more through a groundbreaking number of drip points.

- A thin film of a reflux flow flowing over the diffuser plate is in a direct contact with steam nearby, so that the temperature rises up to a boiling point.

| Type |

Manageable range

of liquid amount |

Variable range of

liquid amount |

Drip point |

Aperture ratio |

| Nozzle Overflow Type |

MIN 50 l/m²H

MAX 80m³/m²H |

1~10 |

1000~2000 point/m² |

50~70% |

OPEN TROUGH TYPE

- Notches on the upper side are sloping to divide the outflow liquid.

- A diffuser plate and clicks on a lower side allow a liquid to spread more through a groundbreaking number of drip points.

- Nozzle overflow type is suitable for a liquid that may block a hole.

| Type |

Manageable range

of liquid amount |

Variable range of

liquid amount |

Drip point |

Aperture ratio |

| Open Trough Type |

MIN 200l/m²H

MAX 80m³/m²H |

1~5 |

1000~2000 point/m² |

50~70% |